Recycling foam #6 can be done using a two step process with densifier and grinder recycling equipment. Learn more about the different recycling processes and recycling equipment.

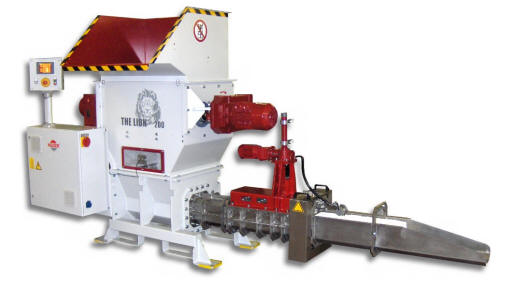

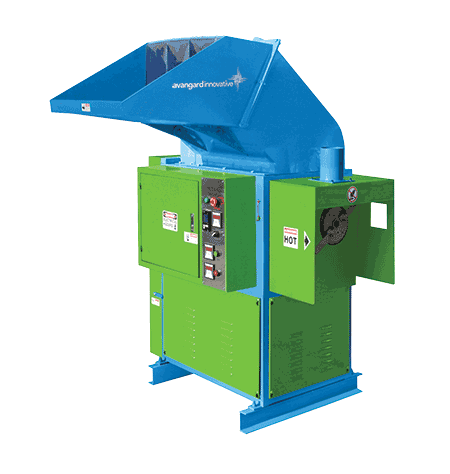

Densifiers

Densifiers are used to compact loose foam products into dense blocks for transportation or storage prior to recycling. While traditional balers can be used to compact the foam, they do not work very well. A 48-foot truckload of baled foam weighs only around 16,000 pounds, whereas a truckload of densified foam weighs 40,000 pounds. New densifiers cost as little as $18,000.

Four commonly used densifiers are hydraulic, thermal, screw drive, and a hybrid.